Company Profile

Forest Print Co., Ltd. is a leading transfer printing company in South Korea recognized in both domestic

and international markets for its differentiated technologies including urethane and silicone 3D transfer printing.

We provide solutions that can most precisely realize brand identity,l and are committed to

creating sustainable value through environmentally friendly processes and a rigorous quality control system.

We provide solutions that can most precisely realize brand identity,l and are committed to

creating sustainable value through environmentally friendly processes and a rigorous quality control system.

Company History

-

20052005 FoundedBegan working with casual brands

-

2008Started collaboration with a domestic outdoor brand

-

2015Expanded business and signed collaboration agreements

with multiple companies -

2018Expanded into the global market.Participated twice a year in online and offline apparel and fabric

exhibitions to research the latest trends and develop insights -

2022DomesticThrough research and development, we developed and analyzed

specialized technologies tailored to fabrics and improved the

adhesion of heat transfer logos to fabric -

2023Established a U.S. branch office.Officially entered the North American market

-

2025현재 진행 중

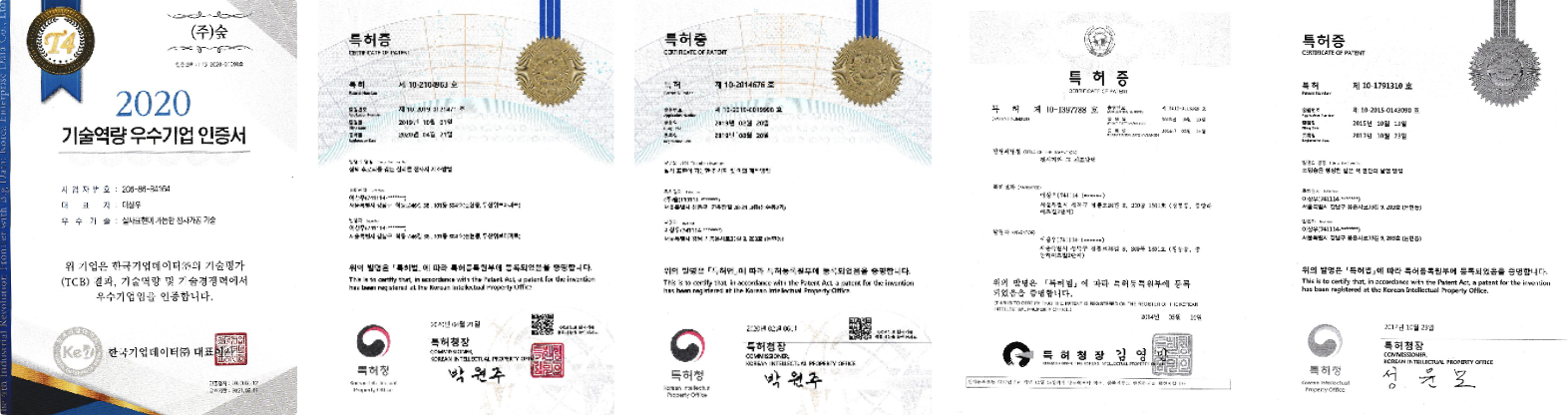

Certifications and technology status

Production facilities

A differentiated transfer printing solution based on automated processes.

Forest Print utilizes automated silk screen printing machines to reliably and efficiently operate all stages of the transfer printing process.

With a systematic production management we can flexibly handle both mass production and small-batch custom production.

Forest Print utilizes automated silk screen printing machines to reliably and efficiently operate all stages of the transfer printing process.

With a systematic production management we can flexibly handle both mass production and small-batch custom production.

-

Quality standardization

Consistent quality is ensured independent of

production operator skill levels -

Minimization of defect rates

Automated precision control reduces defect rates

such as dye migration and color variations -

Accurate rendering wide range of colors

and intricate designsVividly rendering even designs challenging

to manually render -

Cost-effective and

environmentally friendly operationsCost savings and wastage minimization

through reduced defect rates